With the oncoming arrival of our first child, all my music stuff has been kicked out of our house to provide enough space for the impending arrival of our new human

The build threads on ILF are how I found this website so I thought it was time to share a little something back with community here. Also there doesn't seem to be a whole bunch of studio/soundproof room build information online which don't use specialised, expensive products such as Gib acoustic systems, Resilient Clips, Green Glue etc so I wanted document my build in case others were interested doing something similar. The major prerequisite for this was that everything had to be readily available from local hardware stores. Finally, I am hoping that documenting the build here will be a good way to motivate me to actually get on with it and complete it!

The room will be free standing (i.e. not attached to the garage walls), approximately 3 m wide x 3.5 m long x 2.3 m high and fits into the back corner of our garage. It consists of a timber frame construction which is bolted in place to the concrete floor of the garage. The outside of the framing is clad with 12 mm thick plywood cladding and two layers of 10 mm thick plasterboard (Gib, Sheetrock, Drywall etc depending on your geographical location) will line the internal walls of the framing. The wall cavities will be filled with Earth Wool insulation.

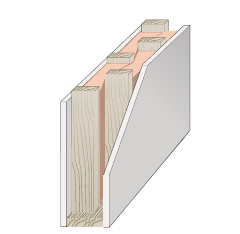

The biggest consideration that I had to take into account was decoupling the walls to reduce noise transfer. A quick Google search indicated that there seem to be a number of different methods to be able to do this but they generally all tend to use specialised products that are relatively expensive particularly given the location where I live. The most promising design that meet my requirements was using offset or staggered timber wall studs to decouple surface of the external cladding from the internal wall surfaces. A double layer of plaster board on the internal surfaces will hopefully provide enough mass and rigidity to avoid resonance issues... Will have to provide an update on this when its completed.

I stole the image below of the off set wall studs from an insulation website but it should give some idea behind the idea.

The walls and roof unfortunately won't be decoupled at the corners but I am hoping some post build internal acoustic treatment may help with any issues caused by this.

I drew up my own plans which are pretty basic but the key thing was to make sure that the center of every second stud was spaced at 1200 mm so I could use a standard sheet of plasterboard or sheet of plywood to minimise cutting and waste of timber/plasterboard. If anyone is interested I can post my shitty plan drawings but they probably only make sense to me and not anyone else.....

Anyway, time for some photos.

The garage pre-build....Apologies for the ubiquitous piles of crap and junk that our garage has accumulated. I had to remove some old shelving from the area in which the room will go (back left corner) before this photo.

The cleared space and mocked-up layout (green masking tape).

Treatment of the concrete floor to stop moisture rising through the concrete. Two coats of Damp Stop seems to be doing the trick so far. I am also going to put a layer of plastic down before the underlay and carpet go on.

Framing timber. The top and bottom plates as well as the end studs are all 90 mm by 45 mm structural timber and the bottom plates are treated to a higher standard than the other pieces of timber in case of any water/moisture ingress. The studs and dwangs (nogs, blocking, whatever you call it in your area!) are all 75 mm by 45 mm to provide the decoupling between wall surfaces.

First frame built...

... and in place with the second the frame. Since both of these frames are free standing next to the external walls of the garage, I had to put the plywood cladding on before moving the frames inside. They were rather weighty..

The next two wall frames featuring the doorway. All the frames bolted down. Starting to look like a room now..

Grainy pic of the offset studs. Hard to capture in a photo unfortunately.

Roof framing in place. I realised rather quickly that getting the roof framing in place after the walls were up was going to be challenging as there wasn't much space to move between the garage roof framing and the wall framing of the room. This meant building the roof frame insitu which was a fun exercise...

Inside the space. Picked up the insulation which now adds to the piles of crap that our garage holds. Managed to get 20 bales of insulation off cuts from that were going to be discarded at various building sites around town for less than $200. This should be enough to line the room and also some extra insulation for our house.

Building paper on and awaiting the remaining plywood cladding..

Plywood cladding is now on and the electrical wiring has begun. Photos to come.