Started up the tolexing. I happened to have enough left over from a 1x12 project (still in progress) to cover it in one piece, so that worked out well. I also can't speak to the longevity of the glue. I only applied it today, and I don't as of yet have any concerns, but take it for what it's worth.

Tl;dr: pick a glue that can bond wood to plastic, and RTFM.

For the glue I used original DAP Weldwood, and while I've read some forum posts on other sites about folks having trouble with contact cement, I think it's a case of following instructions. I've never tolexed before, but I would have no reservations recommending it so someone else. Just make sure that you:

a) Dry-fit like it's your job. Know where any seams and bends are going to end up, mark them, and stick to the markings. The way (DAP, at least) works is you apply adhesive to both surfaces, let them sit for 15-20 minutes, and then press the surfaces together to bond them. You really only have one chance to bond the two surfaces, but they can be re-wetted so it's really very forgiving, and if you mess up it's almost definitely because you didn't plan/dry-fit well enough.

b) Don't rush. I applied glue to the pine, then the tolex, and then another layer to the pine, and then let it sit for 20 minutes. Weldwood has a working time of 2 hours so there's no need to rush (your adhesive product may vary), and it really, really needs the time to set-up. I suspect a lot of the negative reviews for contact cement in this application are from people who tried to cheat the set-up time. Apply the cement, watch an episode of something, and then come back to it.

Also, contact cement fumes are no joke. Do this in a well ventilated area.

I did the top, the sides (separately), and then the bottom, where the joint in the tolex would be. Before I even bought glue I figured out where I wanted the seam and how much overlap there would be, and then I marked everything on the backside of the tolex so I'd know exactly where to apply the glue. Again: figure this all out before you glue anything.

When gluing up the seam I secured the short side, covered it with painter's tape, and then brought the long side over. I found where I wanted the joint and, using a metal square, ran a brand-new utility knife blade through the tolex/tape/tolex sandwich and into the wood underneath. Then I was able to peel back and discard the overlapping vinyl and tape (the tape prevented glue from getting on the short-side of the vinyl), giving me a perfect butt joint.

Again: I've never tolexed before, but here it is in full sunlight (the tolex is dark blue in everything except direct sun). The two edges still overlap where the roundover starts, because I've only glued the flat faces of the cab. I should be able to have the rest of the tolex glued on by the end of the week, and will hopefully have another post up whenever that happens.

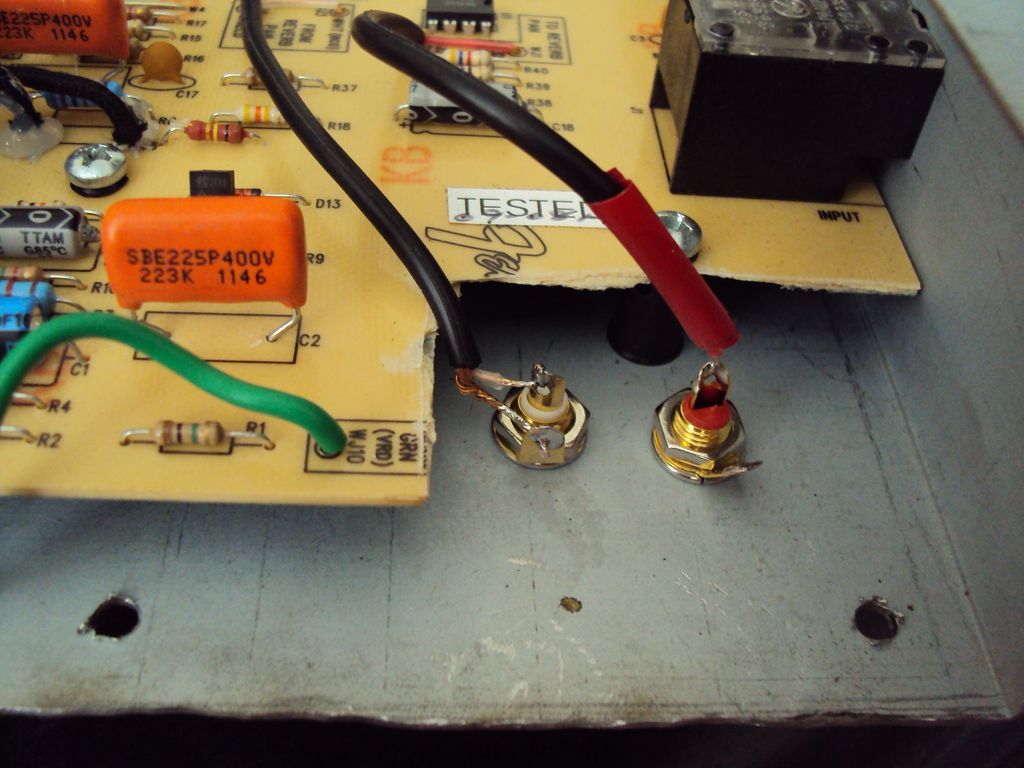

Next update: finish tolexing; chassis/pcb pictures, hardware (?).