Page 1 of 2

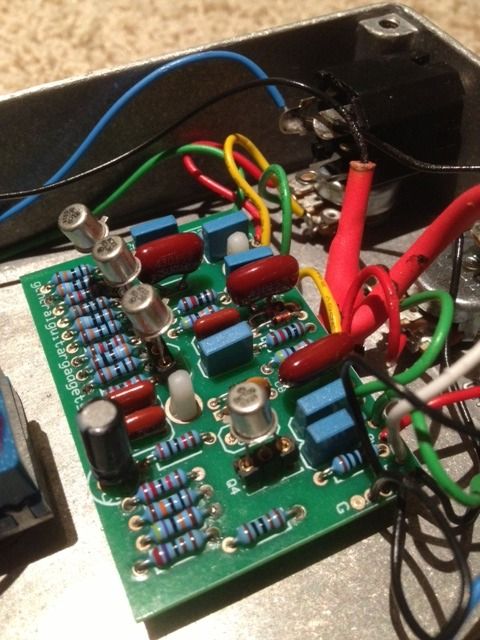

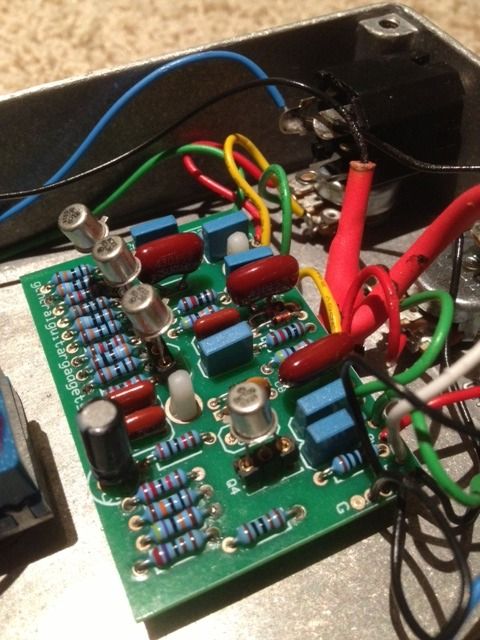

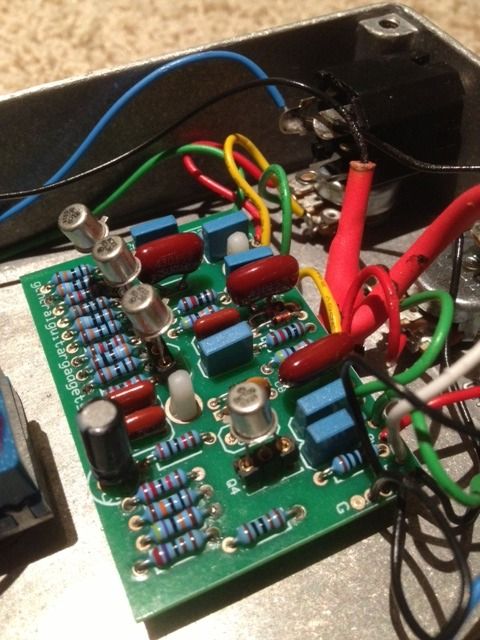

Built my first Muff

Posted: Fri Dec 21, 2012 1:18 am

by guitarslinger21

Used a GGG kit. Did it to Red Army Overdrive Specs

Guts aren't so pretty, but it sounds great.

Here's where I fail at posting a vid.

FUCK IT!

Here';s the link:

http://www.youtube.com/watch?v=ziAwAiiMX3A

Re: Built my first Muff

Posted: Fri Dec 21, 2012 10:44 am

by Arcane

Nice! Love the metal cans - BC109s? The wiring, like everything else, just takes practice. My humble suggestion would be shortening the wires on your next build. It will make it a little quieter and neater. Sounds great!

Re: Built my first Muff

Posted: Fri Dec 21, 2012 11:05 am

by guitarslinger21

Arcane wrote:Nice! Love the metal cans - BC109s? The wiring, like everything else, just takes practice. My humble suggestion would be shortening the wires on your next build. It will make it a little quieter and neater. Sounds great!

Yep, Motorola NOS BC109's.

Actually, the length of the wires ended up being kind of a blessing in disguise.

For a few reasons, I had to unsolder/resolder a ton of stuff on the under side of the PCB. The wire length made this a lot easier. I hopefully won't have the same set of problems next time, so I'll go for cleaner wiring the next time around.

Mistake #1: Instead of using my own solder, with which I have lots of practice, and I know exactly how it's going to react, I used the stuff in the kit. It didn't want to stick to my wires. It was also tougher to get a good shiny joint out of it. I'm not sure how this stuff is different, but I didn't like it. Maybe it's lead free or something. As soon as I started resolding stuff with my own solder, it was like T1000 coming together with a brain of it's own. It just flows to the right spot and sticks to the right things, and always finishes shiny. Lesson learned.

Mistake #2: I installed some trannies the first time around, and didn't use sockets. I thought the trannies might have been the problem, and figured I would make sure it had sockets so I could swap to my heart's content. It was a tough job. My solder vacuum doesn't seem to work any more. Bought a desoldering braid from Radio Shack. Couldn't get it to suck up solder. I ended up just heating each joint in series and rocking it out. With the left over solder, I just used a needle and my iron to make a hole. It worked quite well, actually. I don't know why I was having so much trouble with the wick and vacuum.

I learned a LOT on this build, and I can't wait to do my next one!

Re: Built my first Muff

Posted: Fri Dec 21, 2012 12:29 pm

by Bellyheart

Good work. Sounds great.

Re: Built my first Muff

Posted: Fri Dec 21, 2012 4:30 pm

by Arcane

That does sound like lead free solder which is a little more dull and has requires more heat. That is odd though as I would not think GGG would send out that type of solder. One would think most people buying GGG kits would be rocking a Radio Shack 25 watt iron or the like which would not work all that well with lead free solder. Led free can also ruin your tips pretty quick. Which reminds me, make sure you clen the tip after every round of soldering. Do this frequently! I like to use steel wool in a small glass jar. Using a wet sponge is just a bad idea.

I personally do not use sockets unless the person I am building for really wants to have the option of transistor experimentation. Sockets are great but the can lose a transistor or two over time or with wear and tear. If I am not 100% sure on the transistor scene I just make sure to check the transistor (pinout, etc) with my multimeter before commiting to solder. You get used to the pinout of certain types after you have been at it a while. Always good to check gain though so you get an idea of what ranges work for your preferences.

I find that solder suckers suck. Haha. I am not a big fan unless you have something (vice) to hold the board while you heat the pad and use the sucker. I prefer the braid myself. You just need to get the right technique down of heating the pad/wire to the point where the solder flows into the braid. It takes a little practice but what doesn't?

Re: Built my first Muff

Posted: Fri Dec 21, 2012 10:44 pm

by stripes

man i love what you play in that video. and the pedal looks great, too.

Re: Built my first Muff

Posted: Sat Dec 29, 2012 10:45 pm

by benjuro

Well done on the Muff! Those GGG boards are nice but can be tough for noobs...components are packed in there tight!

Arcane wrote: Which reminds me, make sure you clen the tip after every round of soldering. Do this frequently! I like to use steel wool in a small glass jar. Using a wet sponge is just a bad idea.

I've always used (and been told to use) a wet sponge. Why a bad idea?

Re: Built my first Muff

Posted: Mon Dec 31, 2012 1:47 am

by guitarslinger21

stripes wrote:man i love what you play in that video. and the pedal looks great, too.

THank you!!!

benjuro wrote:Well done on the Muff! Those GGG boards are nice but can be tough for noobs...components are packed in there tight!

I've always used (and been told to use) a wet sponge. Why a bad idea?

Thank you very much!

Yeah, I use the wet sponge too. My tip stays pretty clean

Re: Built my first Muff

Posted: Mon Dec 31, 2012 9:52 pm

by Arcane

benjuro wrote:Arcane wrote: Which reminds me, make sure you clen the tip after every round of soldering. Do this frequently! I like to use steel wool in a small glass jar. Using a wet sponge is just a bad idea.

I've always used (and been told to use) a wet sponge. Why a bad idea?

In my experience the thermal shock from the wet sponge to the hot iron tip will shorten the life of the tip - especially so if you have a cheap (beginer) iron. Using steel wool or brass shavings takes the crud and excess off of the tip but leaves the tip lightly tinned and protected. It also vastly speeds up recovery time. I switched a long time ago and my tips last ages and they never get all gunked up.

Re: Built my first Muff

Posted: Sat Jan 05, 2013 9:08 am

by benjuro

Thank you, definitely going to try it!

Re: Built my first Muff

Posted: Sat Jan 05, 2013 4:02 pm

by mathias

If you can't find the brass shavings easily, these are rather cheap and fit the bill:

http://www.amazon.com/Hakko-Cleaner-599 ... 000PDQORU/It's the only thing we used at the Milwaukee Makerspace; sponges not allowed!

Re: Built my first Muff

Posted: Sat Jan 05, 2013 7:12 pm

by Arcane

Just plain old steel wool will do the trick as well but the copper shavings and/or proper tip cleaner in the link is great.

Re: Built my first Muff

Posted: Sat Jan 05, 2013 8:03 pm

by benjuro

WOW that's pretty slick...thanks for the link

Re: Built my first Muff

Posted: Sat Jan 05, 2013 8:05 pm

by Arcane

Alot of soldering stations actually come with the shavings and holder.

Re: Built my first Muff

Posted: Mon Jan 07, 2013 2:36 pm

by Bret608

Looks really cool!

I think GGG is sending out lead-free solder. At least I've seen comments on build reports elsewhere indicating that's the case. Which isn't so bad as long they tell people!