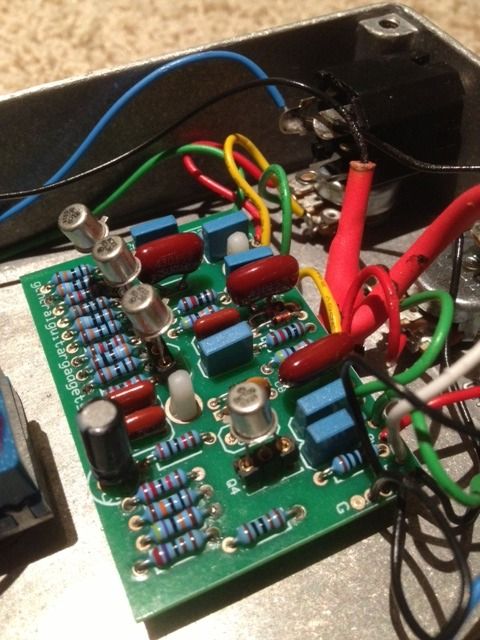

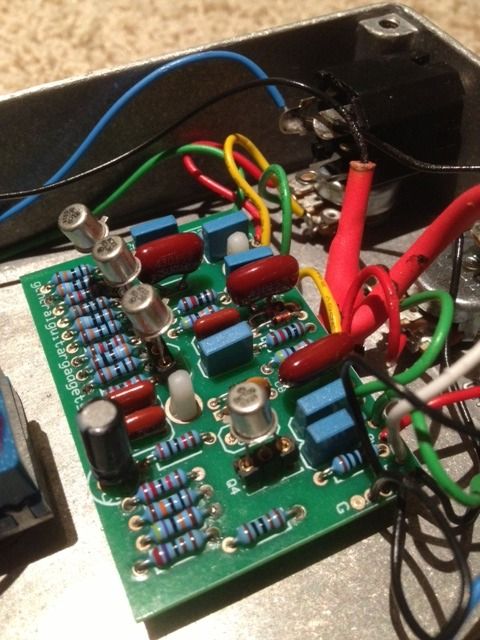

Guts aren't so pretty, but it sounds great.

Here's where I fail at posting a vid.

FUCK IT!

Here';s the link:

http://www.youtube.com/watch?v=ziAwAiiMX3A

Moderator: Ghost Hip

Arcane wrote:Nice! Love the metal cans - BC109s? The wiring, like everything else, just takes practice. My humble suggestion would be shortening the wires on your next build. It will make it a little quieter and neater. Sounds great!

Arcane wrote: Which reminds me, make sure you clen the tip after every round of soldering. Do this frequently! I like to use steel wool in a small glass jar. Using a wet sponge is just a bad idea.

stripes wrote:man i love what you play in that video. and the pedal looks great, too.

benjuro wrote:Well done on the Muff! Those GGG boards are nice but can be tough for noobs...components are packed in there tight!

I've always used (and been told to use) a wet sponge. Why a bad idea?

benjuro wrote:Arcane wrote: Which reminds me, make sure you clen the tip after every round of soldering. Do this frequently! I like to use steel wool in a small glass jar. Using a wet sponge is just a bad idea.

I've always used (and been told to use) a wet sponge. Why a bad idea?

Searching for that new sound.skullservant wrote:You can like whatever you want so long as it makes you happy

mathias wrote:If you can't find the brass shavings easily, these are rather cheap and fit the bill: http://www.amazon.com/Hakko-Cleaner-599 ... 000PDQORU/

It's the only thing we used at the Milwaukee Makerspace; sponges not allowed!