Blues Jr head project

Posted: Tue Jul 26, 2016 7:24 pm

So I'm back after a few-month internet hiatus, and I want to show off share my Blues Jr head project in case someone else finds it useful/inspirational. This has been 'in progress' for several years (I don't think I've had the amp's cab for at least five), but I've only recently started working on it in earnest.

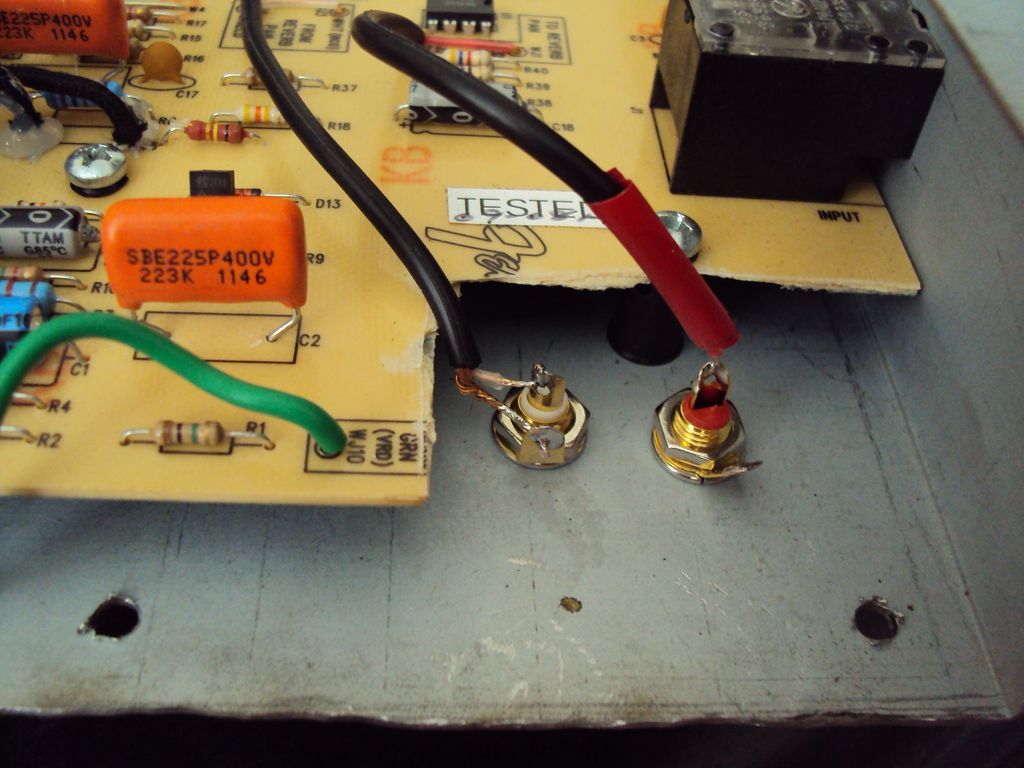

The amp itself has been pretty heavily modified. So far I've done:

- tone stack mod (mids function like a twin's)

- adjustable bias

- cathode follower

- on/off footswitch for reverb

- presence control

- C10 has a jumper (possibly related to oscillations?)

- longer reverb tank

- chassis has been re-drilled and tube board has been re-oriented, so the tubes are on the same face as the transformers

And maybe a few other things. I went through most of the easier/bang-for-buck stuff on Bill M's page, but I didn't take good notes. Like I said: I've been working on this amp for a while.

So now I'm making a proper head cab for the thing. The cabinet itself isn't anything fancy: it's just 1x8 select pine (you know, for tone( )) from Home Depot, put together with butt-joints and then doweled. The joinery looks like shite because a) my cabinetry skills are weak and b) it was going to be tolexed anyway. The pine was a bit warped, and to square everything up I needed to reduce the total depth from it's original 7.5" to about 7". It's not ideal, because some of the knobs and switches will protrude further than the cab, but so be it. If I could do it again with 1x10 I probably would.

)) from Home Depot, put together with butt-joints and then doweled. The joinery looks like shite because a) my cabinetry skills are weak and b) it was going to be tolexed anyway. The pine was a bit warped, and to square everything up I needed to reduce the total depth from it's original 7.5" to about 7". It's not ideal, because some of the knobs and switches will protrude further than the cab, but so be it. If I could do it again with 1x10 I probably would.

Here's the cab, ready to be tolexed. Overall dimensions are about 18" wide, 7.5" tall, and 7" deep. It's very snug to the B Jr chassis, and as a point of reference is a bit smaller than a Sovtek Mig 50.

The amp itself has been pretty heavily modified. So far I've done:

- tone stack mod (mids function like a twin's)

- adjustable bias

- cathode follower

- on/off footswitch for reverb

- presence control

- C10 has a jumper (possibly related to oscillations?)

- longer reverb tank

- chassis has been re-drilled and tube board has been re-oriented, so the tubes are on the same face as the transformers

And maybe a few other things. I went through most of the easier/bang-for-buck stuff on Bill M's page, but I didn't take good notes. Like I said: I've been working on this amp for a while.

So now I'm making a proper head cab for the thing. The cabinet itself isn't anything fancy: it's just 1x8 select pine (you know, for tone(

Here's the cab, ready to be tolexed. Overall dimensions are about 18" wide, 7.5" tall, and 7" deep. It's very snug to the B Jr chassis, and as a point of reference is a bit smaller than a Sovtek Mig 50.