This is going to be my first pedal build. I was thinking of building it on a breadboard first to tweak my values, and then once I'm set on the design wiring it up P2P in a MXR style enclosure. Is this a good strategy?

So far I've ordered a NKT275 spec'd for Rangemasters, and am now investigating the different options for parts/construction for my build. I kind of don't want to go with a kit and PCB/turret/Perf board construction, and want to keep it really clean. Just a single level knob, a LED, and a foot switch.

I'm going for a sound close to the Mid boost setting on the Keeley Java/Analog Man Beano, and plan on tweaking the input cap to hit that spot, and don't intend to utilize a tone control.

I plan on using a socket for the tranny in the pedal, so I can swap in and out different ge transistors for tweaking the design. I have the OC44 Keeley, and want to compare the NKT275, and AC128(or 7?) versions to it to see which I like best.

Also, I plan on wiring it up with a PNP tranny wired for NPN instead. What do I need to watch out for if anything?

Anybody have any good references/tips for wiring up such a pedal?

Gonna build a Rangemaster clone.

Moderator: Ghost Hip

Forum rules

The DIY forum is for personal projects (things that are not for sale, not in production), info sharing, peer to peer assistance. No backdoor spamming (DIY posts that are actually advertisements for your business). No clones of in-production pedals. If you have concerns or questions, feel free to PM admin. Thanks so much!

The DIY forum is for personal projects (things that are not for sale, not in production), info sharing, peer to peer assistance. No backdoor spamming (DIY posts that are actually advertisements for your business). No clones of in-production pedals. If you have concerns or questions, feel free to PM admin. Thanks so much!

6 posts

• Page 1 of 1

Re: Gonna build a Rangemaster clone.

I think the p2p would work better without a socket, since those things usually seem to be made to fit into board holes. Maybe just try the different transistors when you breadboard it? Or maybe you have a good plan worked out, just thinking out loud! Seems like it will be a great project. I built a silicon fuzzface point to point, just spiderwebbed between the jacks and pots, and it worked out pretty well, and it looks glorious inside there. My advice would be to draw out what you're going to to on paper first, it really helps, even though it's only a 2D representation of what will end up being a 3D component web. Also, maybe get 1/2 watt resistors instead of 1/4, because they have thicker leads and it helps solidify things some. Likewise, orange drop caps or mallory 150's will be bigger and have longer and fatter leads, nice for point to point. Fun way to build.

Also, idk what your level of experience is, but man, flux is great, be sure to slob some on each connection before you solder it, and the solder will flow onto everything real nice. Make sure you make a good mechanical connection before you solder, too, the solder is meant to be the finishing touch on an already good connection. This will be extra important since there's no board. I just twist the leads once or twice, or sort of wrap one around the other. Also, those little washers with teeth (lock washers, I guess they're called?) might be a good idea, to keep jacks and pots from eventually loosening and moving around, twisting the component web inside.

Also, idk what your level of experience is, but man, flux is great, be sure to slob some on each connection before you solder it, and the solder will flow onto everything real nice. Make sure you make a good mechanical connection before you solder, too, the solder is meant to be the finishing touch on an already good connection. This will be extra important since there's no board. I just twist the leads once or twice, or sort of wrap one around the other. Also, those little washers with teeth (lock washers, I guess they're called?) might be a good idea, to keep jacks and pots from eventually loosening and moving around, twisting the component web inside.

-

morange

- FAMOUS

- Posts: 1384

- Joined: Thu Oct 22, 2009 3:50 pm

- Location: Montesano, WA

Re: Gonna build a Rangemaster clone.

morange wrote:I think the p2p would work better without a socket, since those things usually seem to be made to fit into board holes. Maybe just try the different transistors when you breadboard it? Or maybe you have a good plan worked out, just thinking out loud! Seems like it will be a great project. I built a silicon fuzzface point to point, just spiderwebbed between the jacks and pots, and it worked out pretty well, and it looks glorious inside there. My advice would be to draw out what you're going to to on paper first, it really helps, even though it's only a 2D representation of what will end up being a 3D component web. Also, maybe get 1/2 watt resistors instead of 1/4, because they have thicker leads and it helps solidify things some. Likewise, orange drop caps or mallory 150's will be bigger and have longer and fatter leads, nice for point to point. Fun way to build.

Also, idk what your level of experience is, but man, flux is great, be sure to slob some on each connection before you solder it, and the solder will flow onto everything real nice. Make sure you make a good mechanical connection before you solder, too, the solder is meant to be the finishing touch on an already good connection. This will be extra important since there's no board. I just twist the leads once or twice, or sort of wrap one around the other. Also, those little washers with teeth (lock washers, I guess they're called?) might be a good idea, to keep jacks and pots from eventually loosening and moving around, twisting the component web inside.

Awesome tips/ideas, thanks man. My level of skill is very basic. Very limited soldering/wiring experience with guitar wiring, and speakers. I'm going to bone up on basics as I'm ordering parts piece meal until I get everything I need.

I do understand the importance of flux and tinning connections though, the first thing my step father explained to me when he showed me how to solder.

Oh, and I actually got the socket idea from another Rangemaster clone build I saw when investigating today, and the wiring was clean as a whistle.

-

The Mad Titan

- committed

- Posts: 401

- Joined: Mon Jul 14, 2014 10:12 pm

Re: Gonna build a Rangemaster clone.

Oh nice, haha. Yeah I learned to solder the wrong way, just fucking up until I got it right.

-

morange

- FAMOUS

- Posts: 1384

- Joined: Thu Oct 22, 2009 3:50 pm

- Location: Montesano, WA

Re: Gonna build a Rangemaster clone.

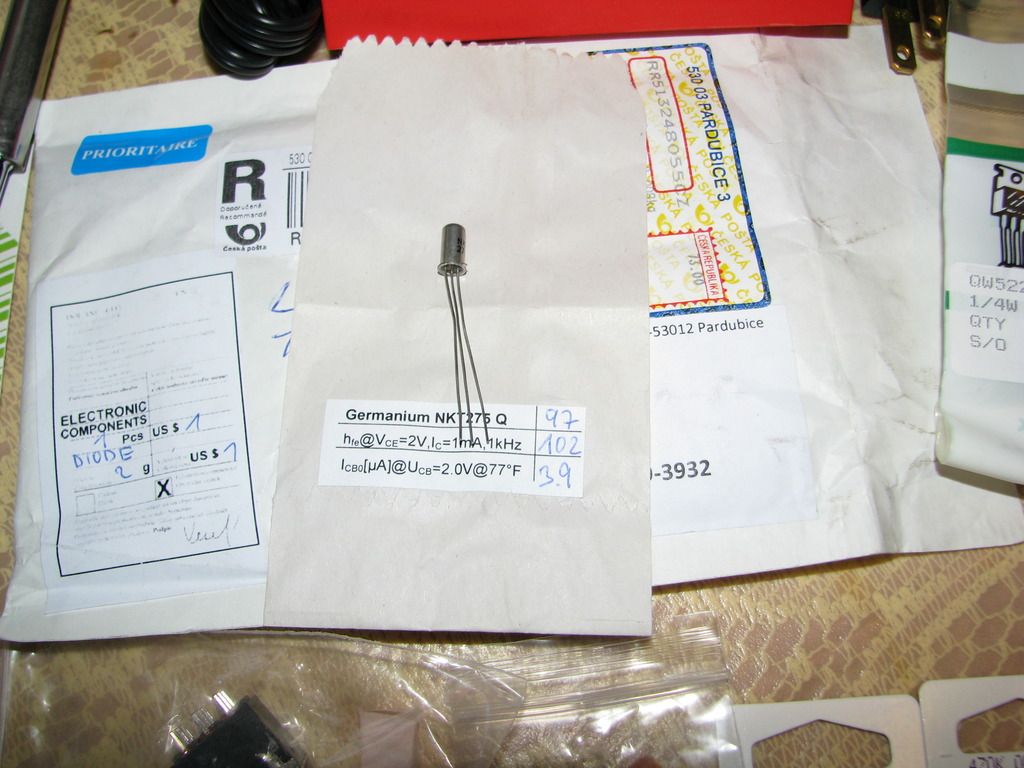

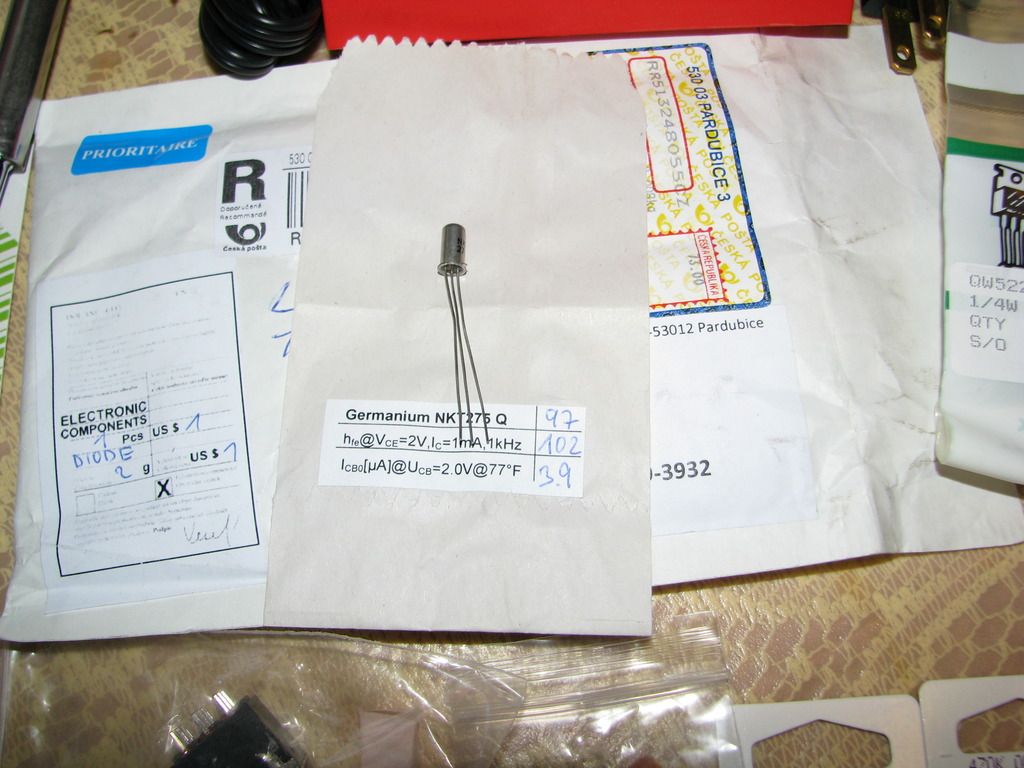

Since last we spoke all this (and more you can't see because of ILF's image size limit) has happened.

The NKT275's landed a cpl weeks ago, and I picked up the Weller and all the other pictured stuff today.

Later this week I'm going to order the enclosure, and pick up a section of 4x8 ply to use as a mount for the breadboard and pedal enclosure.

Color me

Edit: Had to add commas (take a breath). Whew.

Fuckit so excited can't contain myself gonna explode with happy-happy-joy-joy feelings of infinite euphoria.

Until I plug shit in the first time and it doesn't work.

The NKT275's landed a cpl weeks ago, and I picked up the Weller and all the other pictured stuff today.

Later this week I'm going to order the enclosure, and pick up a section of 4x8 ply to use as a mount for the breadboard and pedal enclosure.

Color me

Edit: Had to add commas (take a breath). Whew.

Fuckit so excited can't contain myself gonna explode with happy-happy-joy-joy feelings of infinite euphoria.

Until I plug shit in the first time and it doesn't work.

-

The Mad Titan

- committed

- Posts: 401

- Joined: Mon Jul 14, 2014 10:12 pm

Re: Gonna build a Rangemaster clone.

If you want to know what everything is, it's the parts list from this:

http://www.geofex.com/Article_Folders/R ... tboost.pdf

With a NKT275 instead of the OC44, and a few different input caps to play with.

http://www.geofex.com/Article_Folders/R ... tboost.pdf

With a NKT275 instead of the OC44, and a few different input caps to play with.

-

The Mad Titan

- committed

- Posts: 401

- Joined: Mon Jul 14, 2014 10:12 pm

6 posts

• Page 1 of 1

Who is online

Users browsing this forum: No registered users and 18 guests